Gas preparation system

Special selection of the components of the gas mixture (argon + CO2 + n-pentane) provides the limited streamer operation mode of the chamber. For the preparation of the gas mixture in the experiment, the system similar to the one involved earlier in the NUSEX project is used.

Gas preparation system includes: gas-cylinders with argon and carbon dioxide, inlet valves for gas intake velocity regulation, containers for n-pentane and antifreeze (ethylene glycol), compressor for antifreeze cooling, pumps, ensuring circulation of ethylene glycol in order to maintain the required temperature in the tank with n-pentane, control stand. During the blow, argon and CO2 comes into mixer at a rate specified by a control unit manually and set by electronic blow speed controllers. Thereafter, the gas mixture passes through the tank B with the liquid n-pentane and saturates with its vapor at a room temperature. The obtained mixture comes into tank C, where it passes through n-pentane maintained at a specified temperature. In tank C the excess of n-pentane saturated vapor condenses, and thus the necessary percentage of the component in the gas mixture is provided. Tank A is used to fill the system with n-pentane and prevent air in the gas mixture. Tank D contains antifreeze which is used for thermal stabilization of n-pentane in tank C. Inlet valves for argon and carbon dioxide provides velocity of the gas intake in the range from 0 to 100 l/h with 1% precision and reproducibility of ± 0.2%. The temperature of n-pentane in the tank C is maintained within the specified limits using a temperature sensor inside the tank and the temperature control unit. When the n-pentane is heated over the established limit, the pump starts to circulate antifreeze that cools the tank until the temperature of n-pentane returns within the specified ranges. Antifreeze temperature is also supported in the pre-set limits by the compressor of the refrigeration system and a similar monitoring system. This ensures the constancy of temperature inside the tank C within ±0.3° and the constancy of n-pentane vapor pressure, and, consequently, the percentage of n-pentane in the gas mixture.

Gas preparation system includes: gas-cylinders with argon and carbon dioxide, inlet valves for gas intake velocity regulation, containers for n-pentane and antifreeze (ethylene glycol), compressor for antifreeze cooling, pumps, ensuring circulation of ethylene glycol in order to maintain the required temperature in the tank with n-pentane, control stand. During the blow, argon and CO2 comes into mixer at a rate specified by a control unit manually and set by electronic blow speed controllers. Thereafter, the gas mixture passes through the tank B with the liquid n-pentane and saturates with its vapor at a room temperature. The obtained mixture comes into tank C, where it passes through n-pentane maintained at a specified temperature. In tank C the excess of n-pentane saturated vapor condenses, and thus the necessary percentage of the component in the gas mixture is provided. Tank A is used to fill the system with n-pentane and prevent air in the gas mixture. Tank D contains antifreeze which is used for thermal stabilization of n-pentane in tank C. Inlet valves for argon and carbon dioxide provides velocity of the gas intake in the range from 0 to 100 l/h with 1% precision and reproducibility of ± 0.2%. The temperature of n-pentane in the tank C is maintained within the specified limits using a temperature sensor inside the tank and the temperature control unit. When the n-pentane is heated over the established limit, the pump starts to circulate antifreeze that cools the tank until the temperature of n-pentane returns within the specified ranges. Antifreeze temperature is also supported in the pre-set limits by the compressor of the refrigeration system and a similar monitoring system. This ensures the constancy of temperature inside the tank C within ±0.3° and the constancy of n-pentane vapor pressure, and, consequently, the percentage of n-pentane in the gas mixture.

Scheme of gas preparation system.

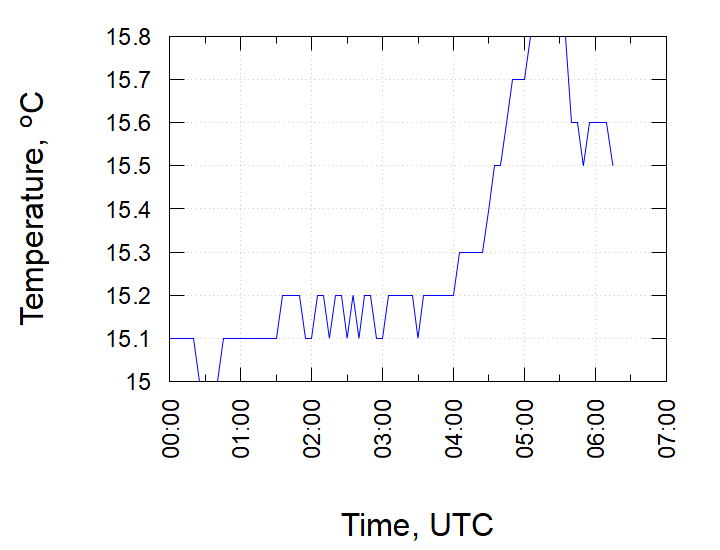

METEO-data

Moscow, MEPhI, NEVOD